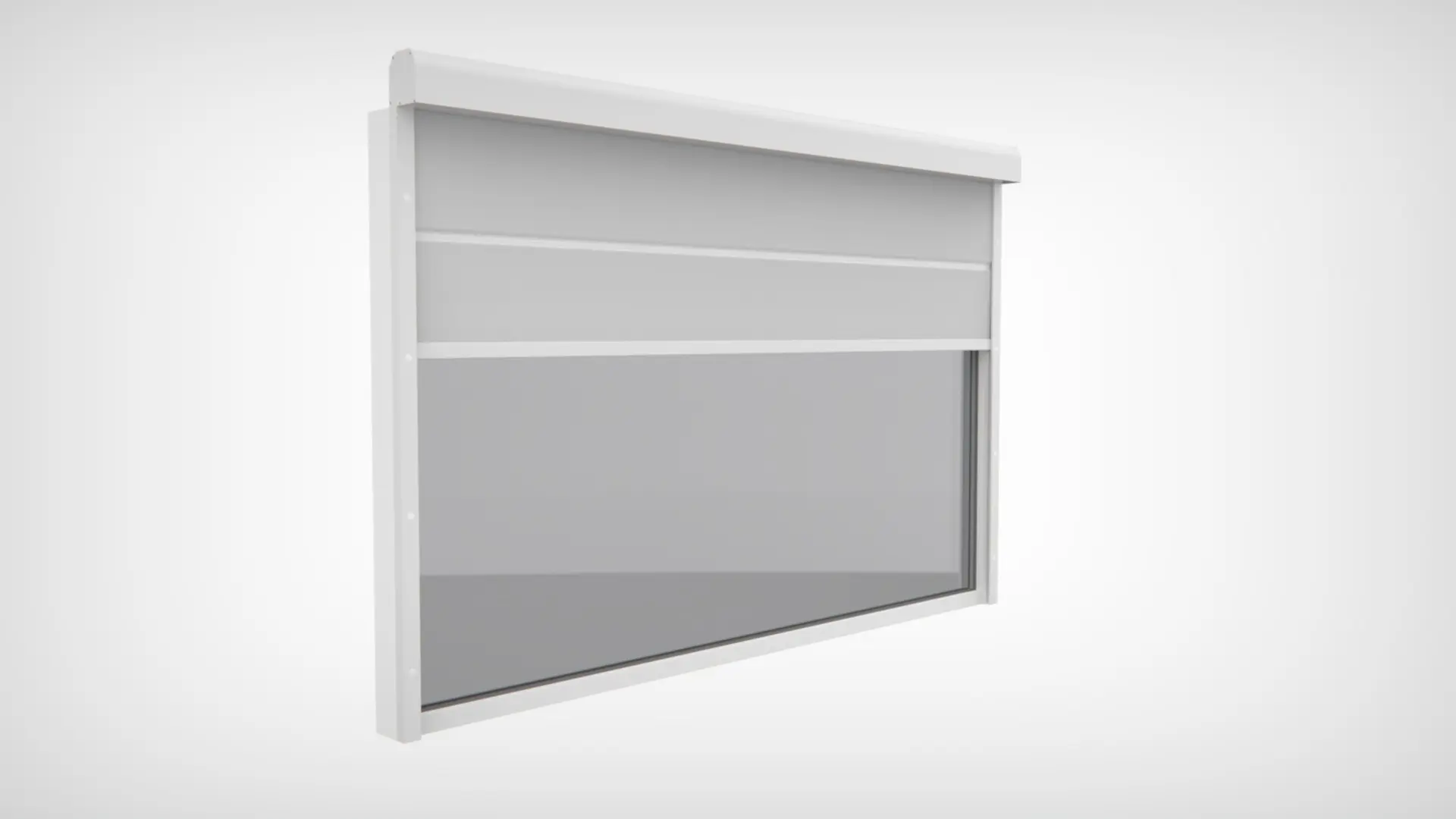

We are proud to present our latest innovation in sun protection: a groundbreaking "ZIP" system that sets a new standard for eco-friendly solutions. Our new system is unique in that it is completely independent of fabric type, giving you complete freedom to choose the most environmentally friendly options without compromising functionality.

Environmentally Friendly and Flexible

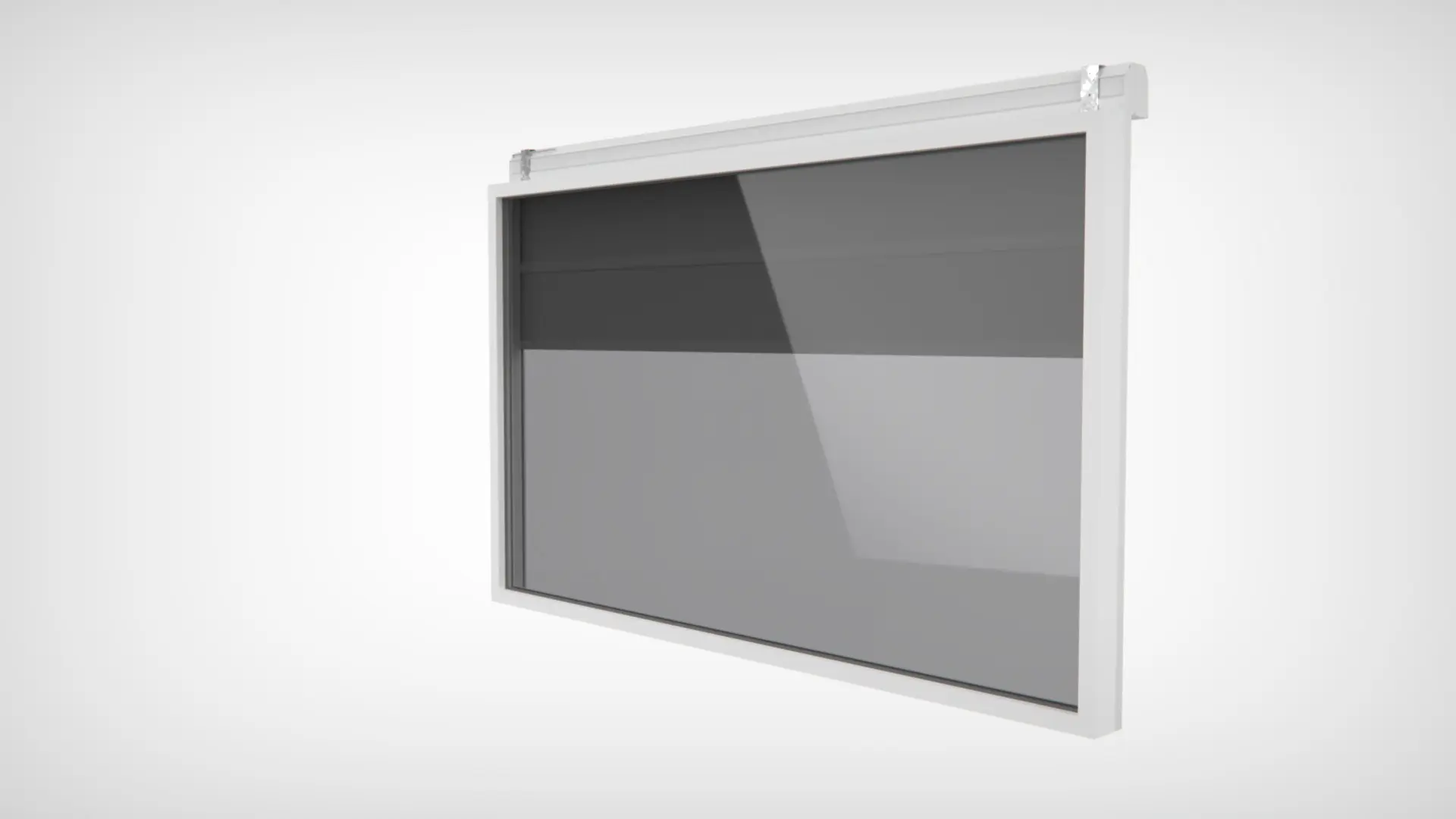

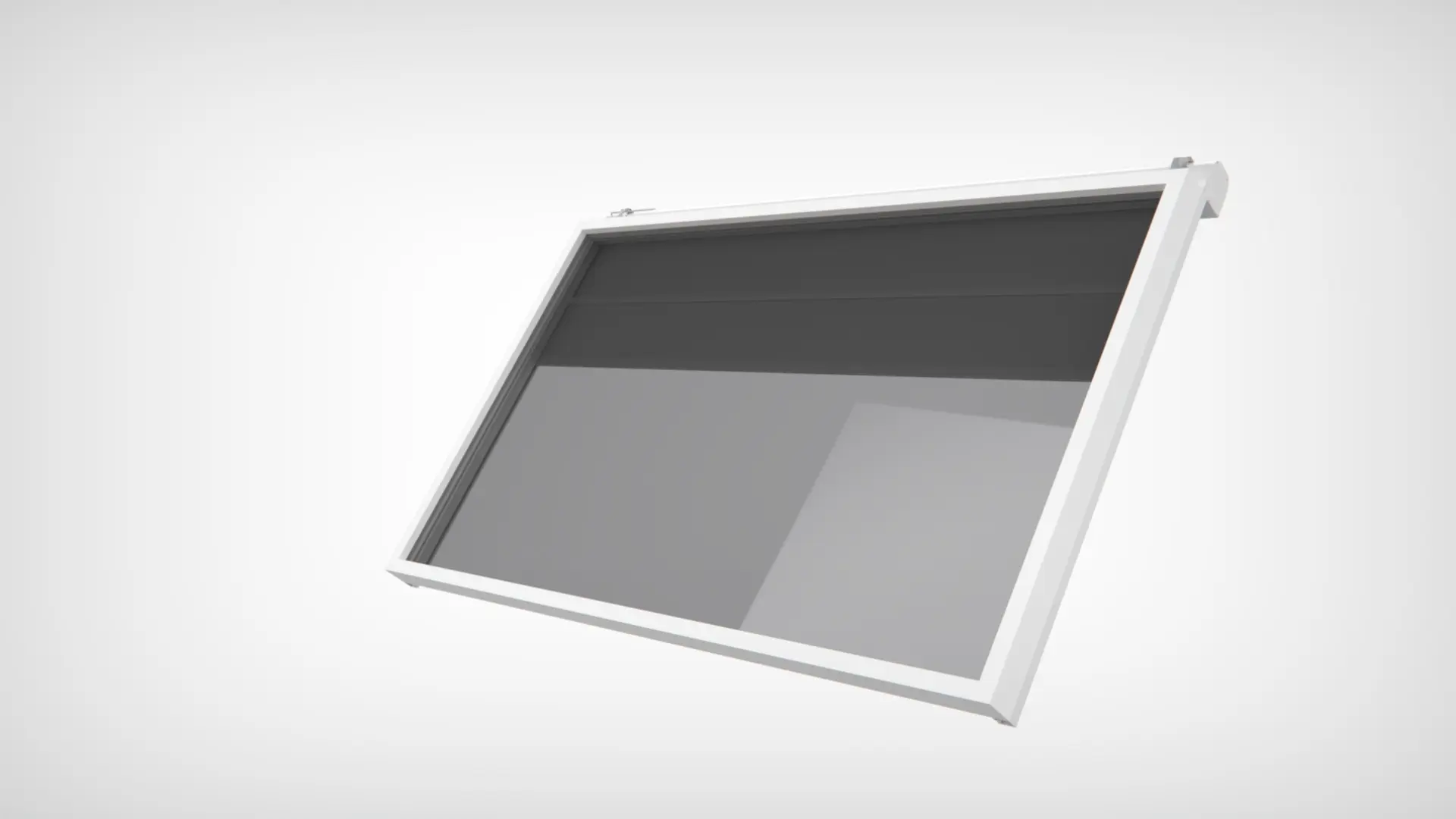

Unlike traditional systems, our "ZIP" system requires no PVC-based materials and eliminates the need for welding during the manufacturing process. The innovative construction, utilizing a patented locking method, ensures a secure and durable attachment without zippers or similar solutions. This enables the use of eco-friendly fabrics that are better for both the environment and your health.

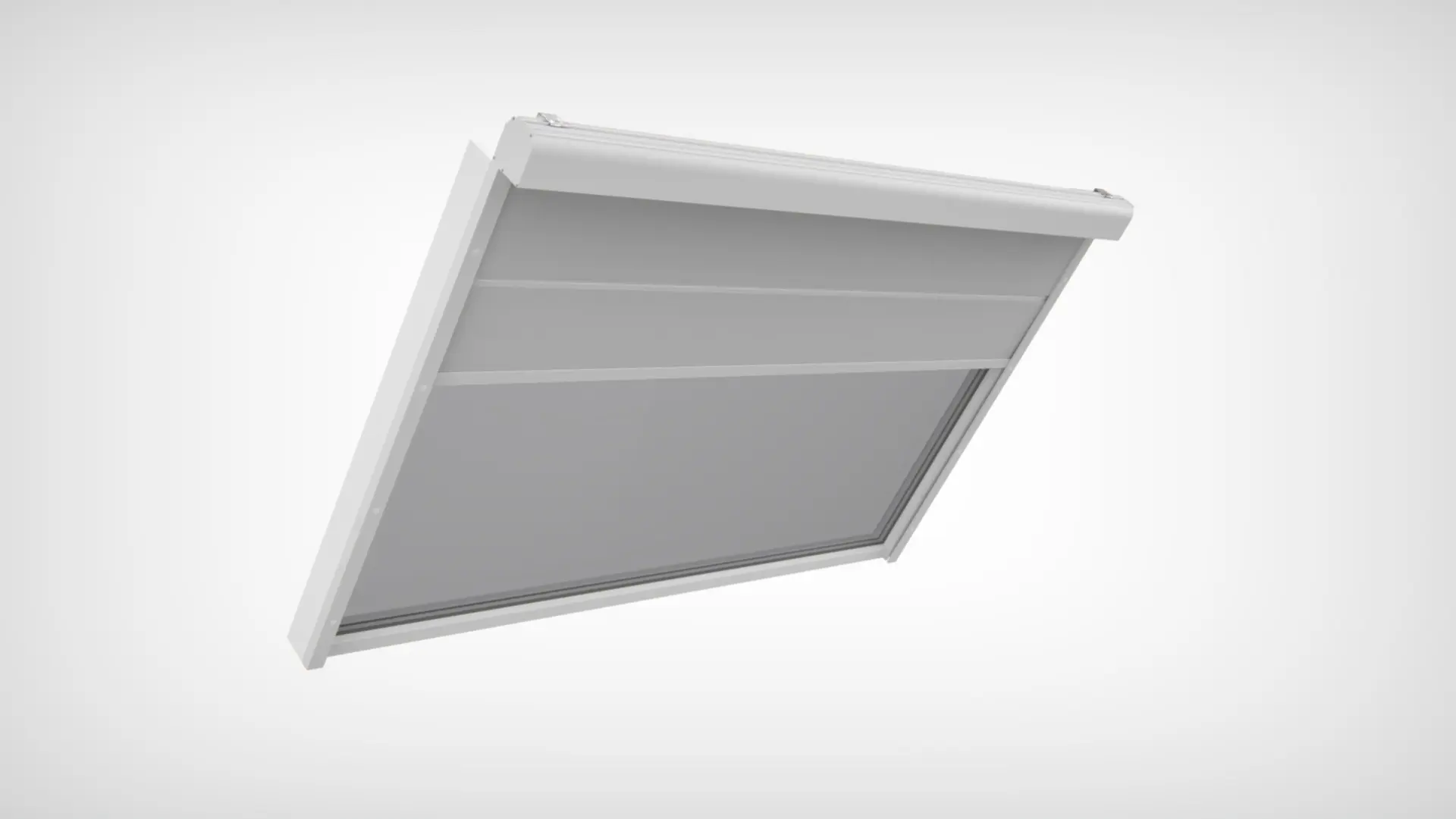

The system can be installed at various angles and can be used for both interior and exterior applications, making it ideal for horizontal and vertical skylights as well as angled windows.

User-Friendly Installation and Maintenance

Our system also offers a range of practical benefits. It is designed to be easy to install and maintain, reducing both time and costs for you as a customer. The flexibility of the system means it can be adapted for all types of windows, including horizontal and vertical skylights and angled window sections, both indoors and outdoors.

Key Benefits at a Glance:

- Environmentally Adapted: Choose from a wide range of PVC-free and eco-friendly fabrics.

- No Welding: Simplified manufacturing process without the need for welded seams.

- Flexible Applications: Suitable for horizontal skylights, angled windows, and various installations.

- Easy Installation and Maintenance: Saves time and money for both installers and users.

- Economical and Sustainable: A solution that combines environmental benefits with long-term cost-effectiveness.

Our new "ZIP" system offers an unbeatable combination of environmental and economic benefits without compromising on quality or functionality. Choose our patented solution for a future-proof and sustainable installation.

In traditional ZIP systems, PVC (polyvinyl chloride) is often used because it is highly suitable for high-frequency welding (HF welding). PVC has unique molecular properties that allow it to be welded quickly and efficiently using electromagnetic waves, creating strong and durable seams. A common application of PVC is in the edge of ZIP systems, where half a zipper is welded on using this method. PVC is also flexible, durable, and relatively cost-effective, making it a popular choice in many industries.

The production of PVC involves chlorine and other chemicals that can release hazardous byproducts like dioxins, which are highly toxic and have been linked to serious health issues such as cancer and hormonal disruption.

Use of Additives: To make PVC flexible, plasticizers, often phthalates, are added, which can leach into the environment and cause harmful effects on both animals and humans. Some phthalates are known endocrine disruptors

PVC is difficult to recycle and degrades very slowly in nature. When incinerated, it can release toxic gases, including hydrogen chloride and dioxins, further polluting the environment.

HF Welding: Often used to join PVC, HF welding is energy-intensive and contributes to increased energy consumption, which negatively impacts the environment.

Building Materials Assessment (BVB)

The Building Materials Assessment is a Swedish system that evaluates construction products based on their environmental and health impacts. BVB rates products in categories – Recommended, Accepted, or Avoided – based on the presence of hazardous chemicals and environmental impact throughout the product lifecycle.

PVC materials are rated negatively by BVB due to their content of harmful chemicals like phthalates and the environmental impact associated with production and waste management. Products containing PVC therefore receive a lower rating, which may affect their use in environmentally certified construction projects.

LEED (Leadership in Energy and Environmental Design)

LEED is an international certification system that assesses the environmental performance and sustainability of buildings based on a points system. Points are awarded for energy and water efficiency, material selection, indoor environmental quality, and site selection.

The LEED system encourages the use of low-impact materials and restricts the use of PVC by promoting products that contribute to a healthy indoor environment and sustainable design. Using PVC reduces a building's chances of achieving higher certification levels.

Miljöbyggnad

Miljöbyggnad is a Swedish environmental certification focused on three main areas: energy use, indoor environment, and material selection. Buildings are classified as bronze, silver, or gold, depending on how well they meet these criteria.

Miljöbyggnad closely evaluates materials that impact the environment and health. PVC's negative health and environmental effects lead to a lower certification level if it is used extensively.

BREEAM (Building Research Establishment Environmental Assessment Method):

BREEAM is a global certification system that assesses buildings’ environmental performance based on various factors, including energy use, health, and material selection.

BREEAM encourages the use of sustainable materials and emphasizes a life cycle perspective. The use of PVC, due to its environmental impact and health risks, negatively affects the building's total score.